EDITORS NOTE: While you’ll find most of what you need here already, we are still working on this guide to get it wrapped up with additional details and charts. We expect to have it all the way finished by Monday, August 7th, end of day. Thank you for your patience! Have you been considering adding …

Tag: diy

How to Repair Drywall (4 Ways)

If there’s one thing we’ve learned from doing this video and blog post, it’s that drywall is amazing! It’s easily fixable. If you need to access a pipe or electrical, etc. in a wall, cutting a hole in the drywall is NOT the end of the world. If the kids are being crazy and damage …

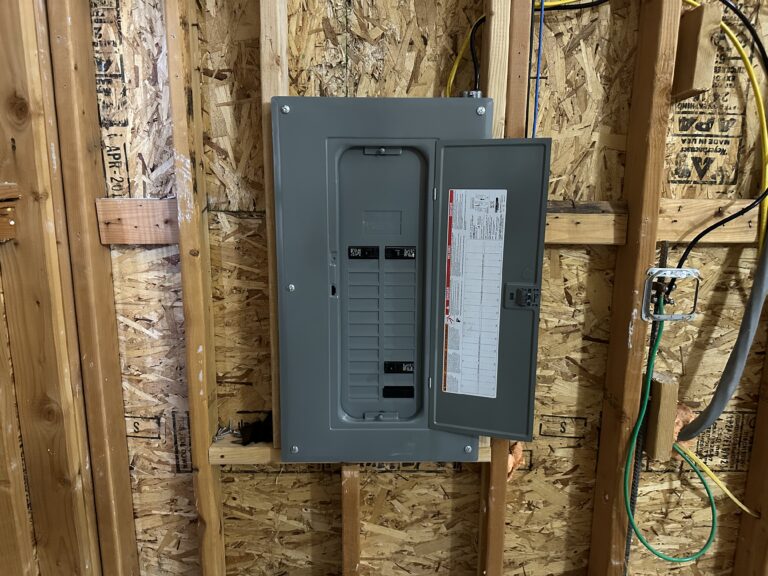

How to Replace Outlets, Light Switches, and GFCI Plugs

Time to upgrade your old outlets and light switches? Look no further. It’s easier than you think. 1- Turn off the Power! Make sure you’ve gone to your circuit breaker box and turned off the power to the outlet or light switch you’re going to be replacing. Once you’ve done that, be sure to test …

$3 DIY Mid-century Modern Plant Stand with Plans!

Making these mid-century modern plant stands is pretty easy and only requires a circular saw as far as power tools. The job is easy with a table saw and router but these are definitely optional. Below you’ll find the plans for both the smaller / lighter plant stand whose legs extend up around the pot …

How to Build an American Girl Doll Bunk Bed

Learn to build a simple but cute bunk bed for 18″ dolls like the American Girl Dolls or the Our Generation line of dolls. This bed size is patterned after manufactured 18″ doll beds and fits the dolls comfortably. The plans use simple and available lumber, including 2x4s or 2x2s, 1x4s, 1/2″ plywood and 1/8″ plywood. …

How to Install Fiberglass Insulation

Installing insulation yourself is not a difficult task. It doesn’t take too long and, contrary to what some believe, is not typically a super-itchy experience. The last couple of times I did this it was easier than I expected and definitely worth doing myself. You don’t need much at all by way of tools, either. …

How to Mount a TV to the Wall, Step by Step

Do you want to get your TV off of a stand on onto the wall like the cool kids? Good news! It’s easy to do and makes a big aesthetic difference.

How to Create the Perfect Retro Games Room

In the face of today’s high-tech games and fast-paced technology, retro gaming is making a major comeback. The BBC reports that more people are collecting and playing with games on systems that dominated the early days of home gaming. These include the Atari 7800s, Nintendo Entertainment System, Sega Master System, and Sony PlayStations of the …

3D Printing: 13 Things I Wish I Knew When I Was Getting Started

Several years ago I read a book called Makers, by Chris Anderson and he talked about how, in the future, we could all have 3D printers of our own and our homes would be like little manufacturing factories. Today, we’re seeing that happen around the world. It’s pretty incredible. A couple of years ago I …

How to Build a Treeless Tree house – Part 1 – Footings and Deck

Once upon a time, we had small children who loved having picnics in the front yard, dressing up like frogs, and playing on a good ol’ swing set.