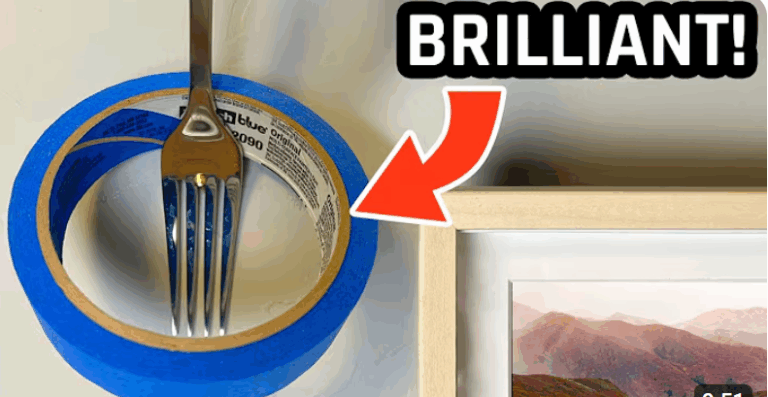

Tired of the same old picture hooks and crooked frames? Discover clever, creative ways to hang pictures without damaging your walls—or your style. In this DIY guide, we’ll share innovative picture hanging ideas that are renter-friendly, budget-conscious, and perfect for adding personality to any space. Here are seven clever picture hanging tips that everyone should …

Category: YouTube

How to Add an Electrical Outlet for a Wall Mounted TV

Are you looking for DIY home improvements to save you a lot of money? My DIY blog posts empower you to tackle home improvements confidently, helping you enhance your space while saving money on labor and materials. Here are just a few:DIY Mini Split Installation: A Complete A to Z GuideWhat Are The Locking Mechanisms …

DIY Central Air Install for $3300.00 (Including Tools)

DIY projects save you money while boosting creativity—discover budget-friendly home improvement tips on our DIY website! You can save so much money with DIY projects. Here are some of my popular posts:How to Install an Electrical Sub Panel for DIYers and Save Thousands of DollarsHow To Repair Drywall (4 Ways)Tips For Lowering Your Winter Heating …

DIY Planter Box for Around $20- Two Versions!

I’ve got a lot of home and garden ideas to beautify your yard and add some summer fun. Here are some of my popular posts that you might like:Essential Spring Landscaping Tips for Your Yard4 Fun Outdoor Lighting Ideas for LandscapingDIY Outdoor Projector Screen SMALL PLANTER BOX WOODWORKING PLANS Get the detailed 12-page plans for …

How to Build a Treeless Tree house – Part 1 – Footings and Deck

Building a treeless treehouse is a fun and rewarding project that lets you create a unique space without relying on large trees. In this DIY guide, we’ll walk you through the first crucial steps: constructing the footings and deck. These foundational elements set the stage for a safe, durable, and level structure. Whether you’re looking …

Don’t Close Your Vents to Redirect Air – I’m Putting it to the Test

Have you ever wondered if you could redirect the airflow in your home simply by closing vents? We put this DIY technique to the test, experimenting with how adjusting your vents can influence the comfort and efficiency of your home. Are you looking for more DIY Home Improvement Ideas to save you money? Check out …

How to Repair Drywall (4 Ways)

I’ve got you covered on your home repairs and DIY projects. Check out some of my favorite posts to get you started. How To Add an Electrical Outlet for a Wall-Mounted TVBuilding a Woodshop from Scratch – Drywall, Mud, Tape, Paint, and Epoxy FlooringDIY Home Projects You Can Do For Little Money If there’s one …

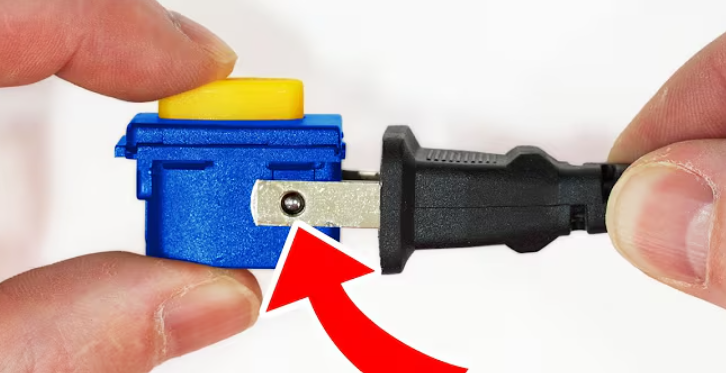

Are Holes in Plugs Totally Useless? Not Anymore.

Don’t miss my amazing posts on Home Fixes You Can DIY. Here are some of my favorites:DIY Home Projects You Can Do For Little Money. Most Common Places Homeowners Forget to CleanHow To Fix Holes in Drywall – 4 Easy Steps In the U.S., our plugs have always had these little 1/8 inch or three-millimeter …

Why Don’t Builders Finish Garage Walls?

You’ve come to the right place if you want to learn everything about DIY. Beautify and safeguard your home with: Easy and Attractive DIY (Faux) Shiplap for about $80.00.The Importance of Sealing Air Leaks In Your HomeHow Do P-Traps Work? 3 Drain Issues to Watch Out ForHave you ever noticed that almost every newly built …

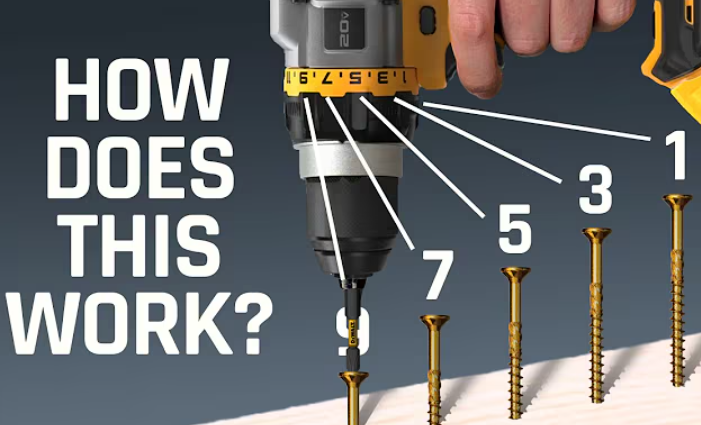

The Most Misunderstood Feature On Your Drill

I am here to help with all your DIY home projects. Here are some great helps and tips for you:5 Drill Features Everyone Should KnowLiving Room Makeover with Vertical ShiplapStop Squeaky Floors on Carpet and Hardwoo I will show you a clutch collar, and we will make sure that you’re totally familiar with it. I’m …