EDITORS NOTE: While you’ll find most of what you need here already, we are still working on this guide to get it wrapped up with additional details and charts. We expect to have it all the way finished by Monday, August 7th, end of day. Thank you for your patience! Have you been considering adding …

Tag: how-to

How to Build an American Girl Doll Bunk Bed

Learn to build a simple but cute bunk bed for 18″ dolls like the American Girl Dolls or the Our Generation line of dolls. This bed size is patterned after manufactured 18″ doll beds and fits the dolls comfortably. The plans use simple and available lumber, including 2x4s or 2x2s, 1x4s, 1/2″ plywood and 1/8″ plywood. …

How to Install Fiberglass Insulation

Installing insulation yourself is not a difficult task. It doesn’t take too long and, contrary to what some believe, is not typically a super-itchy experience. The last couple of times I did this it was easier than I expected and definitely worth doing myself. You don’t need much at all by way of tools, either. …

How to Mount a TV to the Wall, Step by Step

Do you want to get your TV off of a stand on onto the wall like the cool kids? Good news! It’s easy to do and makes a big aesthetic difference.

How to Build a Treeless Tree house – Part 1 – Footings and Deck

Once upon a time, we had small children who loved having picnics in the front yard, dressing up like frogs, and playing on a good ol’ swing set.

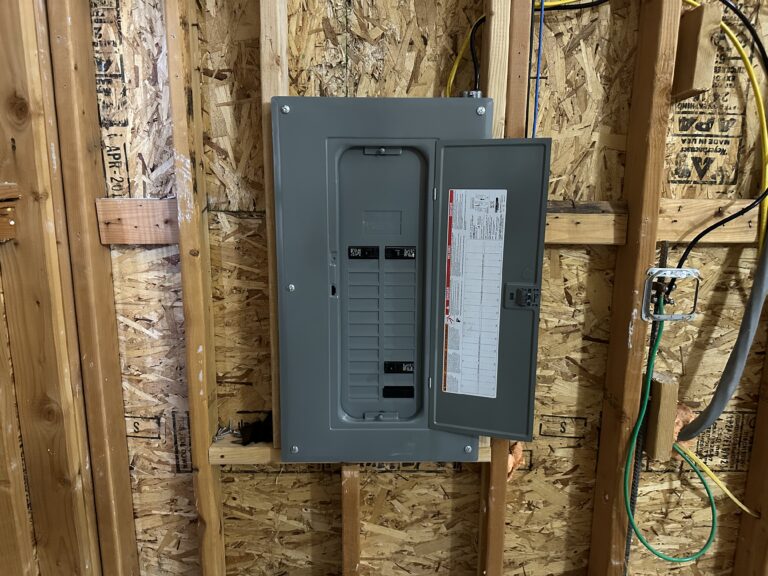

Building a Wood Shop from Scratch – Framing Progress

When we were looking for a new house a few years back, we really hoped to find one with a good amount of space and a three car garage, so that we could park both cars in the garage and then have some room for me to do woodworking and my many projects. We ended …

$23 DIY Planter Box

It’s easy to make these cute planter boxes. They add a lot of charm and dimension to a walkway, porch or patio. GET THE PLANS! Download the plans for this Planter Box here! https://lrn2diy-shop.fourthwall.com/products/23-dollar-planter-box-plans Each box consists of 9 cedar fence pickets and one 2 x 4. You’ll also need 1- 1/4″ screws, 3″ screws, …

DIY Outdoor Projector Screen

The projector screen we’re going to be building is made of PVC and will hold steady in windy areas like where we live. It provides a great picture and is perfect for outdoor movie nights with family and friends. For this project I used a good quality screen material that I purchased from Amazon. …

Standing Desks: Everything You Need to Know

The first thing you need to know is that there are three main types of standing desks: the fixed or traditional standing desk, the Riser and the adjustable-height desk. The fixed standing desk or rig is any setup that allows a person to stand or be upright while working but doesn’t give them the option to sit down. This is a …